CAST NYLON MACHINERY, TECHNOLOGY, KNOW HOW

Polikim Dis. Tic.A.S. builds sophisticated user friendly; machinery, equipment and supplies the complete cast nylon production line with technology and in-depth know how. All the machinery and equipment are made for heavy duty, functional, reliable and easy to operate.

Besides electricity, factory space, pressurised air and the raw materials; the production line is complete for the customer. Polikim Dis. Tic. A.S.will also prepare on request drawings for best space-efficient layout according to your factory building plan.

Polikim Dis. Tic. A.S. also provides technical advice, spare parts, and support on a long term basis.

Polikim Dis. Tic. A.S. will either supply all chemicals such as activators, catalysts, colorants, lubricants, fillers, caprolactam or inform the customer the types and main suppliers of these chemicals.

USE OF STANDARD CAPROLACTAMS IS POSSIBLE

Caprolactam is the main raw material for Cast Nylon production. About 95% of the reactive melt is caprolactam. For the world common technology of nylon casting a special caprolactam (named as AP caprolactam) is required. AP caprolactam is manufactured only by two companies in the world and is very expensive.

The machinery, technology and know-how offered by Polikim Dis. Tic. A.S. allows production of highest quality cast nylons using standard caprolactams. This brings great logistic and cost advantage compared to companies using common technology. Naturally if preferred production with AP caprolactam is also possible.

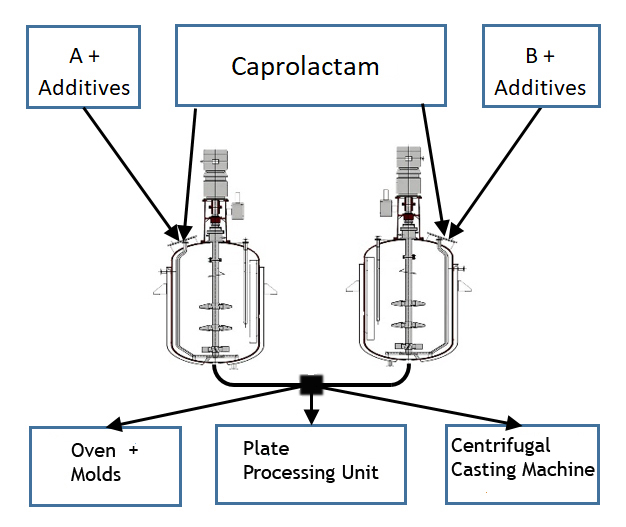

PROCESS FLOW CHART

Cast nylon is produced from caprolactam. Caprolactam is melted in exact proportion with catalyst, activator and different additives, mixed and cast into heated molds. Processing cast nylon requires exact measured quantities of the two-melt components at a precise set temperature, carefull mixing and filling into a heated mold for polymerization to occur. The varying special additives used during the casting process, determine the final performance and attributes of this engineering plastic. The capacity of this product line depends mostly on the type, shape, dimensions of the products and mold quantities.

Cast Nylon production capacity is nearly 200 tons/year in one shift, 500 tons/year in three shifts.